Precise . Quality . Trust

agricultural bevel gearbox

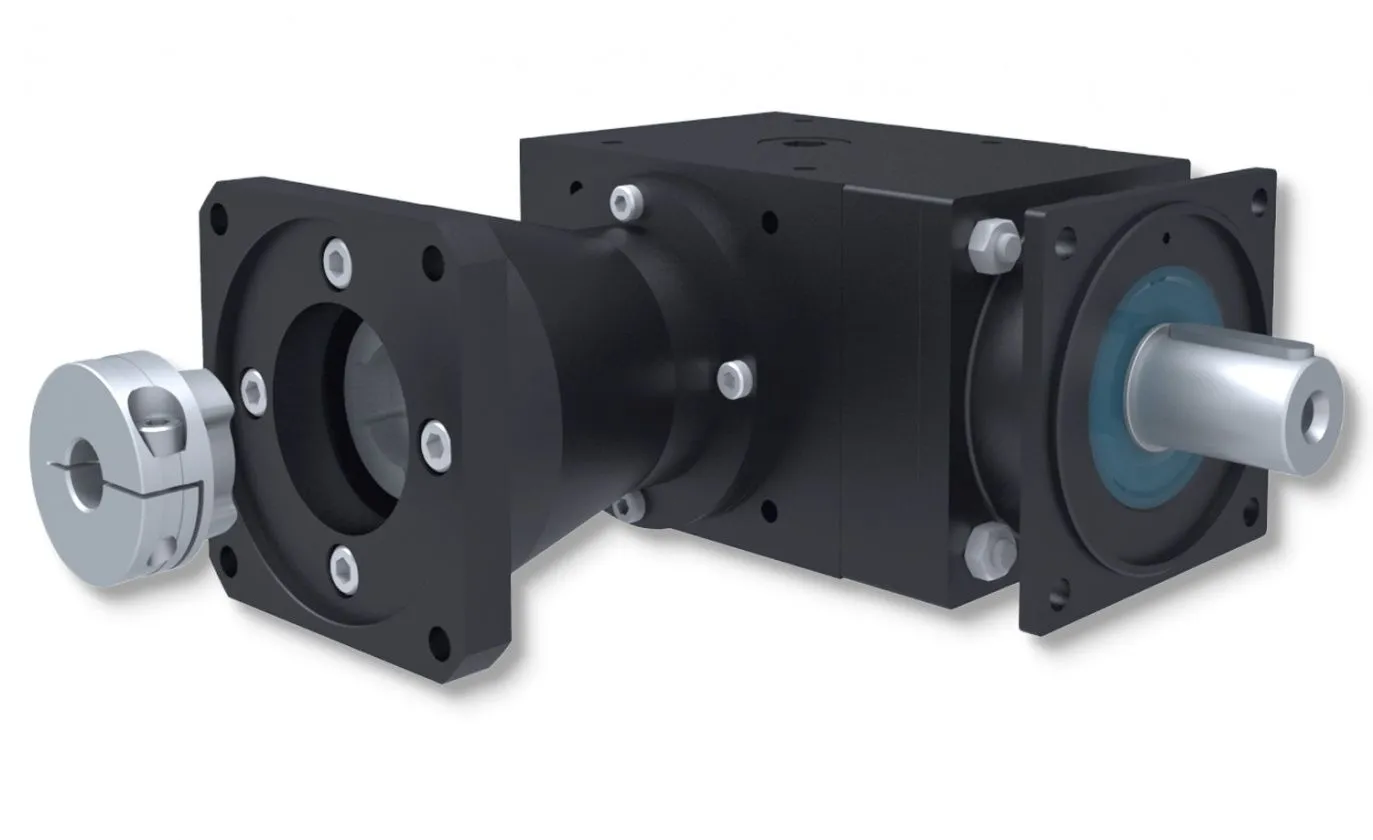

A bevel gearbox is a device used to transmit and/or split/distribute the power of a singular rotating mechanical drive shaft through a defined angle, typically 90°.

What is a bevel gearbox?

There are many different kinds of gearbox – or gearhead, as some prefer – and the bevel gearbox is one of the most commonly used in automation and power transmission applications.

The name refers to the gear within the gearbox – i.e. bevel gears – a single stage unit which simply interlocks the bevelled edges of two gears and transfers the rotation of one to the other, like interlocking fingers.

How a Bevel Gearbox Works

The name bevel gearbox is derived from the gear design used inside the gearbox i.e. bevel gears. The gearboxes are a single stage unit typically supplied with gear ratios within a range from 1:1 to 4:1. They can be supplied in fractional gear ratios as well e.g. 1.5:1.

Bevel gearboxes are ideal when a drive line needs to turn a corner or one drive line needs to power multiple devices from one motor. For example a series of driven rollers on a car production line all driven from 1 motor with each roller at 90° to the main drive shaft and each roller connecting into the main drive shaft via a bevel gearbox.

The Advantages 0f Bevel Gearboxes

Space

Use when installation space is limited

Design

Compact design

Other types

Can be combined with other types of gearbox

Speed

Fast speeds when spiral bevel gears are used

Low-cost

Low-cost alternative to hypoid gearboxes

Bevel Gearbox Catalogue

We are one of the excellent aluminium bevel gearbox suppliers. We are Our gearboxes are extensively specified in applications where compactness, reliability, efficiency and low noise are required.

Browning Bevel Gearbox

Spiral Bevel Gearbox

Aluminium Bevel Gearbox

wholesale bevel gearbox

Our Bevel Gearbox Product

Our company also has other types of plastic spur gear, if you need please contact us.

Bevel Gearbox Assembly: Installation

Normal installation assumes that all shafts are in a horizontal plane, so all bearings and gears are in the oil bath. If any shafts are in a vertical plane, you may need to replace the lubrication options and seal bearings.

Installing the gearbox by connecting it to the input power supply and load also requires key considerations. When driven by sprockets, belts, or gears, radial load calculations must be made to ensure that bearing load limits are not exceeded. It must be aligned within the coupling specification to avoid bearing wear when connected to the coupling.

How Bevel Gearbox Used?

Bevel gearboxes can be realized using bevel gears with straight, helical or spiral teeth. The axes of bevel gearboxes usually intersect at an angle of 90 degrees, whereby other angles are also basically possible. The direction of rotation of the drive shaft and the output shaft can be the same or opposing, depending on the installation situation of the bevel gears.

More about bevel gearbox

90 Degree Bevel Gearbox:The spiral bevel gears in right angle spiral bevel gearboxes meet at 90-degree angles to transfer the directional force along a right angle rather than inline, which gives them a wide variety of applications. The helical teeth present on these spiral bevel gearboxes are also ideal for applications where the drive direction needs to be turned at 90 degrees to drive the wheels. These helical teeth on our spiral bevel right-angle gearboxes also produce significantly less noise and vibration, making them ideal for applications where backlash or noise are a major concern.

The spiral bevel gearbox series is a series of highly reliable, efficient and economical products. The transmission improves torque density, smaller physical structure, higher efficiency, and lower weight, noise and power consumption. Overall, the modular design of the series provides a sustainable and efficient drivetrain that minimizes operating costs and improves usability.

Steering Bevel Gearbox:Bevel boxes for commercial vehicles when direct connection via a ball rail telescopic shaft is not possible due to the relationship between the steering gear and the steering column. Bosch bevel boxes are available in a variety of designs for familiar mounting positions. The usual standard is an axial Angle of 90°.

Get In Touch

WHY CHOOSE US

We are one of the best bevel gearbox manufacturers.We can offer bevel gearbox drawings.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!